Improving Inventory Turnover: Strategies for Increasing Efficiency and Profitability

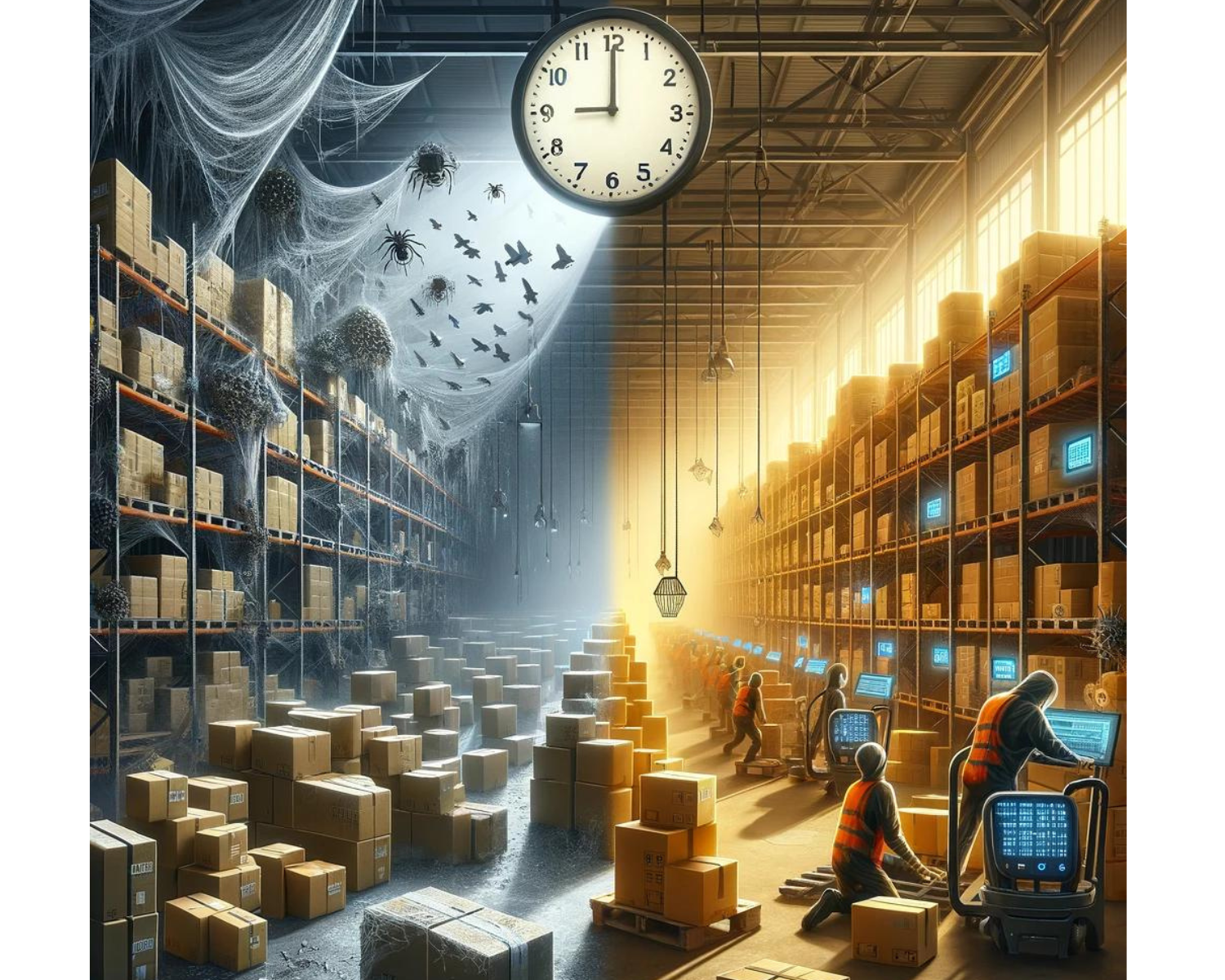

This blog discusses strategies for improving inventory turnover, enhancing operational efficiency, and boosting profitability in businesses dealing with physical products, indicating efficient management and healthy demand.

Understanding Inventory Turnover

Before diving into strategies, it’s important to grasp what inventory turnover entails. It is calculated by dividing the cost of goods sold (COGS) by the average inventory during a period. Improving turnover means either increasing sales, reducing inventory levels, or both. This balance is crucial for minimizing holding costs and maximizing sales opportunities.

Strategies for Improving Inventory Turnover

- Accurate Demand Forecasting

- Implementation: Utilize historical sales data, market trends, and predictive analytics to forecast demand more accurately. Adjust inventory levels based on seasonal variations and market conditions.

- Impact: Reduces the risk of overstocking or stockouts, ensuring that inventory levels are closely aligned with customer demand.

- Efficient Inventory Management

- Implementation: Adopt inventory management systems that provide real-time data and insights, enabling better tracking of stock levels, order processing, and replenishment.

- Impact: Increases operational efficiency, reduces excess inventory and ensures timely replenishment of high-demand products.

- Supplier Relationship Management

- Implementation: Develop strong relationships with suppliers for flexible inventory practices, such as just-in-time (JIT) inventory, which allows for frequent, smaller orders based on demand.

- Impact: Enhances supply chain responsiveness to changes in demand, reducing the need for large inventory holdings and associated costs.

- Diversifying Suppliers

- Implementation: Avoid reliance on a single supplier by diversifying supply sources. This strategy mitigates risks related to supply chain disruptions.

- Impact: Ensures consistent inventory flow and prevents stockouts, maintaining steady sales and turnover rates.

- Optimizing Product Portfolio

- Implementation: Regularly review and adjust the product portfolio based on performance metrics. Focus on high-performing products while discontinuing or reducing slow movers.

- Impact: Improves overall turnover rate by concentrating inventory investment on products with higher demand and profitability.

- Dynamic Pricing Strategies

- Implementation: Employ dynamic pricing models to adjust prices based on demand, competition, and inventory levels. Promotional pricing can help move excess stock.

- Impact: Increases sales velocity for overstocked items, improving turnover and freeing up warehouse space.

- Implementing Cross-Selling and Upselling Techniques

- Implementation: Train sales teams on effective cross-selling and upselling strategies to increase the average order value and move inventory more quickly.

- Impact: Enhances sales without necessarily increasing inventory levels, contributing to a better turnover rate.

- Continuous Improvement and Monitoring

- Implementation: Establish key performance indicators (KPIs) for inventory management and regularly review performance. Use feedback loops to refine strategies.

- Impact: Enables ongoing optimization of inventory levels and turnover rates, adapting to changes in demand and market conditions.

Conclusion

Implementing strategies like demand forecasting, efficient inventory management, and optimized pricing and sales can enhance business efficiency and profitability, aligning inventory with market demand for agility and financial health.

#InventoryTurnover #SupplyChainOptimization #DemandForecasting #InventoryManagement #SupplierRelations #ProductPortfolio #DynamicPricing #CrossSelling #Upselling #OperationalEfficiency #ProfitabilityEnhancement #BusinessStrategy